EurosortDictionary

EuroSort Terms

-

Gentle Push Product Handling

The EuroSort Pushtray, Cross-Tray and Push Bar Sorters use a positive divert to gently push items off the tray and slide them into the chute. This allows for sorting fragile items such as electronics, jewelry, and accessories without damage. -

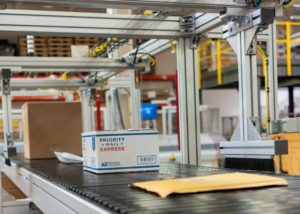

Heavy Duty Tray Options

Designed for the rigors of the postal world, our single split tray sorter is capable of heavy-duty use, with the capacity to sort up to 25 lbs. -

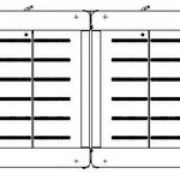

Smallest Discharge Pitch

Our family of sortation solutions have a discharge pitch up to 70% smaller than our competition. This means that we are up to 70% more accurate with the same product. This allows for a smaller sorter footprint, or more destinations in the space you have available. -

Un-Bagged/Loose Item Sorting Capability

The EuroSort family of sortation solutions can handle items with or without a polybag, enabling significant cost savings and helping make our planet a little greener at the same time. -

Manual Induction Ease

Slower sorter speeds, tight tray spacing, and a safe tray design, enable our collection of sortation technology to allow for easy, safe, manual induction to attain the high throughputs required by many of our customers. -

No-Touch Pack Out

Our Split Tray Sorters utilize a patented discharge mechanism which enables an extremely tight discharge pitch. This reduced pitch size allows for smaller sorters, more destinations in the same space, and higher accuracy -

Flex Drive System

The Flex Drive System is designed around utilizing a distributed network of smaller motors to drive the sorter and taking advantage of our patented tray connections to allow for inclines, declines, and positive and negative turns. Bonus! Sorter length is now unlimited, allowing for our sorters to truly adapt to your operation, regardless of how many destinations you need. -

Safe Tray Design

Safety and utility are critical for all our customers, so we designed our trays to be extremely close to each other. Unlike other technology where the gaps between trays make for a less safe, less efficient induction and require higher sorter speeds to maintain throughput, our entire family of sortation solutions take advantage of this safe tray design. -

No-Weld Framework

EuroSort’s family of sortation solutions utilize an 85% aluminum framework that eliminates the need for welding and increases your flexibility for any future expansions as your business grows. -

Flat-Drop Technology

Our family of split tray sorters utilize a patented discharge mechanism to ensure that products discharge from the tray perfectly flat, allowing items to stack safely and securely (without damage) in the destination. -

Quiet As a Mouse Operation

EuroSort has gone above and beyond to design an extremely quiet machine. With noise levels under 70 dB, a EuroSort sorter may well be the quietest piece of machinery you have in your facility. -

Heavy Duty Carrier Option

Designed for the rigors of the postal and consumer goods industries, our Twin Push Tray Sorter is capable of heavy-duty use, with the capacity to sort up to 50 lbs per carrier. -

Bi-Directional Discharge

EuroSort's innovative sweeper design utilizes three paddles distributed evenly around the module allows for discharging to either side without the need to reset the side of the paddle. This allows for smaller gaps between items and an overall higher throughput than other sweepers on the market -

Modular Construction

With an incredibly modular design, the EuroSort Push Bar and Sweeper sorters can, with limited to zero downtime, be extended, modified, moved, or rebuilt to keep up with your operation. -

Low Budget Friendly

Simple mechanisms, modular designs, and no welding allows the EuroSort Push Bar and Sweeper Sorters to be incredibly budget friendly allowing for greater ROI's and easier automation justification.