Split TraySorters

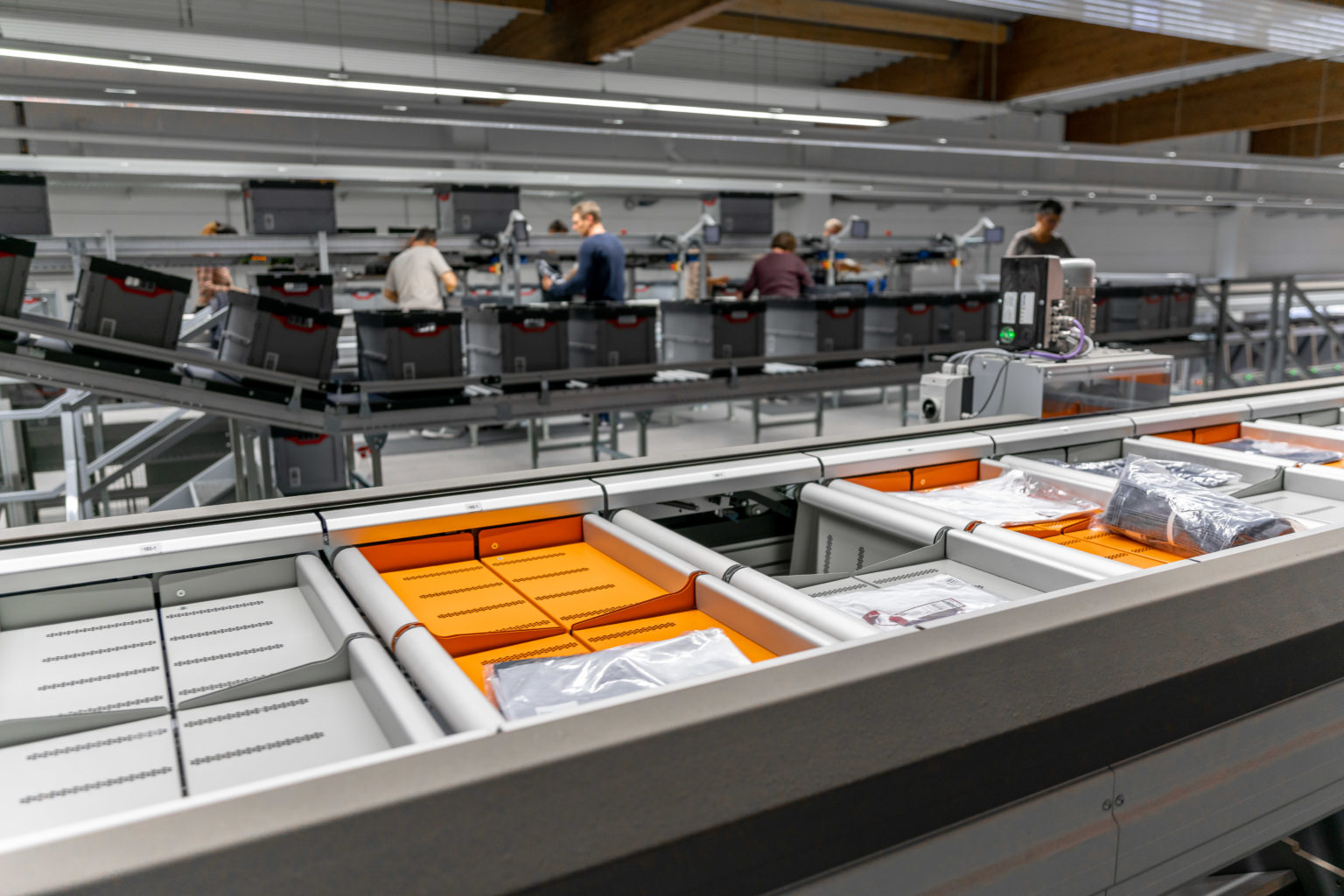

About the Eurosort Split Tray Sorter

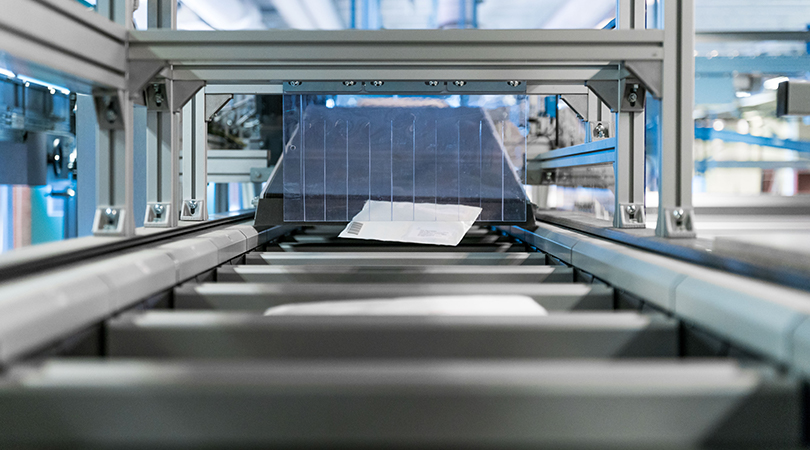

Designed from the ground up as the product that launched the company, the EuroSort Split Tray Sorter (also called a Bomb-Bay (bombay) Sorter or Flat Tray Sorter) has undergone many revisions and improvements over the years, but has never lost the simple functionality that makes our unique Bomb-Bay sorter a favorite in the postal, pharmaceutical, retail, and apparel industries.

A Modern Take on the Split Tray Sorter

The EuroSort Split Tray (Bomb Bay) Sorter, like other bomb bay sorters, discharges items through the tray and into the chute or outbound carton and that’s where the similarities end. Unlike similar bombay sorters on the market, EuroSort’s patented tray design allows items to discharge completely flat into the outbound carton or chute. Not only does this increase our sort accuracy, meaning less re-work and sort errors, but it also reduces the size of your unit sorter, or can allow you to fit more destinations in the same space. More destinations = more efficiency in your operation. Compared to other unit sorters on the market today, this can translate to up to a 50% space savings in your facility, or up to a 50% increase in the size of your pick wave. Worried about throughput? Don’t be! EuroSort’s Split Tray Sorters can achieve from 5,000 items/hour all the way up to 35,000 items/hour depending on your configuration.

Benefits of Split Tray Sorter

- Flat-Drop Technology – Reduces handling at packout, reduces/eliminates product damage, and increases the accuracy and precision of our split tray sorters.

- Manual Induction Ease – Save money, reduce complication, and increase your flexibility with a machine that allows for manual induction.

- Flex Drive System – The EuroSort Flex Drive did away with wheel-style turns, belts, and chains, effectively eliminating the last single point of failure on our sorters and increasing flexibility and reliability.

- Safe Tray Design –No sharp edges, minimal spacing between trays, finger guarding where necessary, and thoughtfully designed touchpoints take the worry out of sortation.

- No-Touch Pack Out – The tightest discharge pitch in the industry enables the sorting of items directly into the outbound carton/tote/container with no secondary touch during packout.

- No-Weld Framework –Easy installation, easy expansion, and superior modularity of your sortation system.

- Heavy Duty Tray Options – Up to 25 lbs on a single tray

- Smallest Discharge Pitch – Increased accuracy allows for a smaller discharge pitch and a denser sorter footprint.

- Un-Bagged/Loose Item Sorting Capability – No polybag no problem. Sort even loose garments with ease.

- Quiet As a Mouse Operation – Noise levels below 70dB

What Throughput Do You Need?

Need more information?

* Indicates a required field